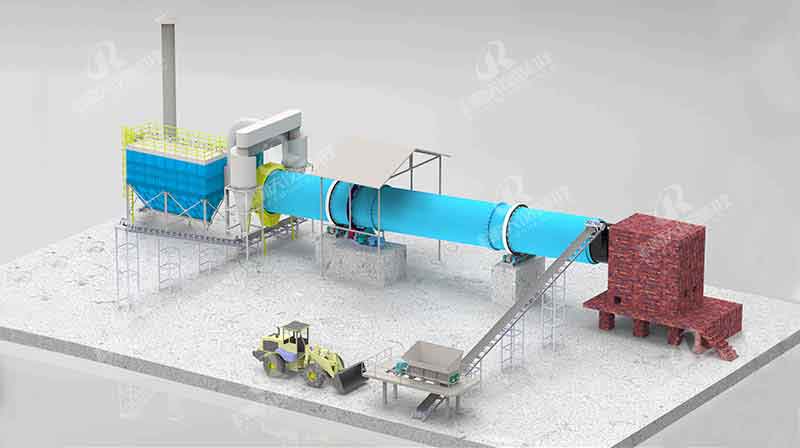

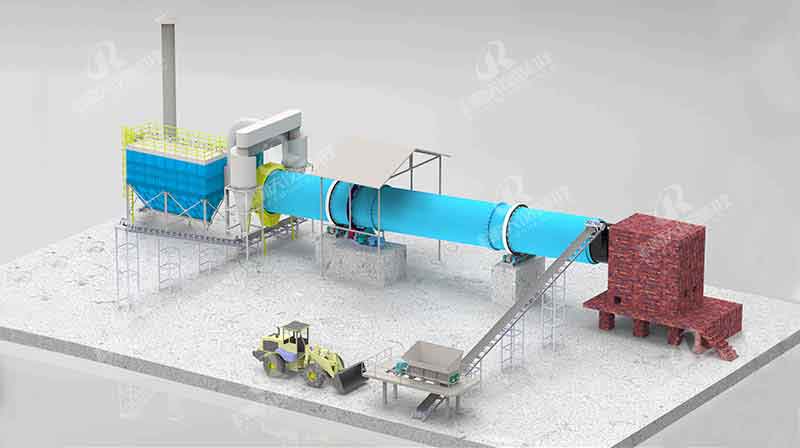

The low temperature calcinating and drying process of gypsum is a combination of drying and calcinating. The system is simple, easy to operate, low energy consumption, The low pressure superheated steam provides a stable heat source. After distribution, measurement and regulation, it is used for drying and heating. At present, there are mainly direct heating rotary kiln, indirect heating rotary kiln, gas flow rapid calcining, boiling furnace calcining, frying pot calcining and other technological modes.

Uniform heating, dynamic calcination, no raw and overburning phenomenon, can be continuous automatic production.

Optimized structure configuration, equipment running stably, can be equipped with complete anti-corrosion, insulation measures according to the requirements.

Circulation heating and drying system, greatly saving energy, equipped with efficient dust removal device, green environmental protection.

The equipment process is simple, the production capacity is large, the equipment operation is safe and stable.

|