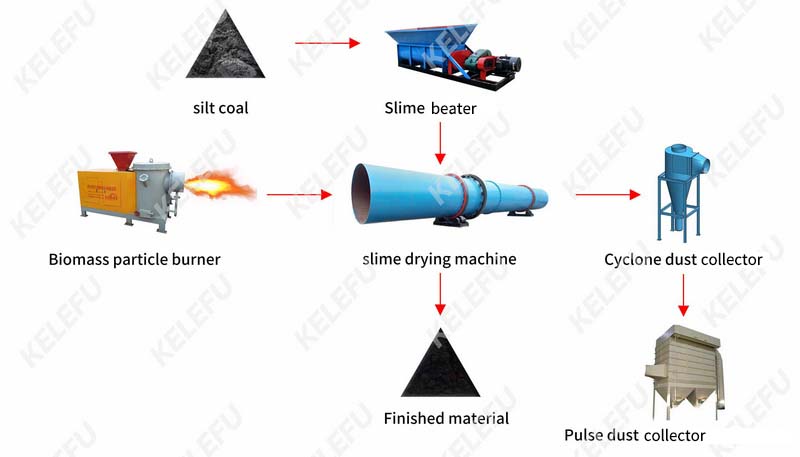

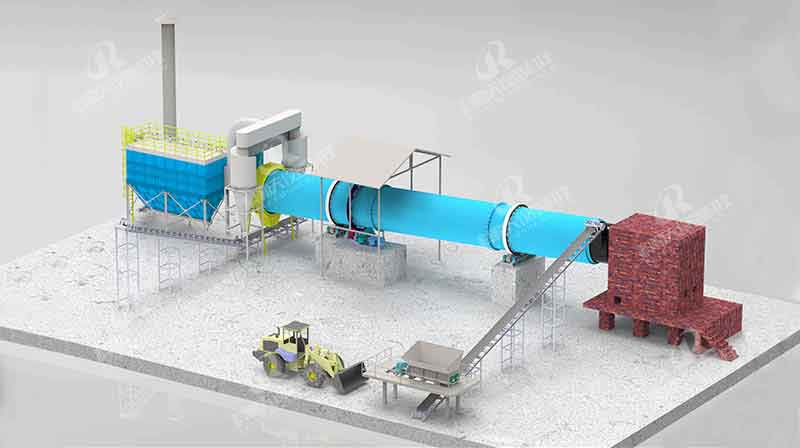

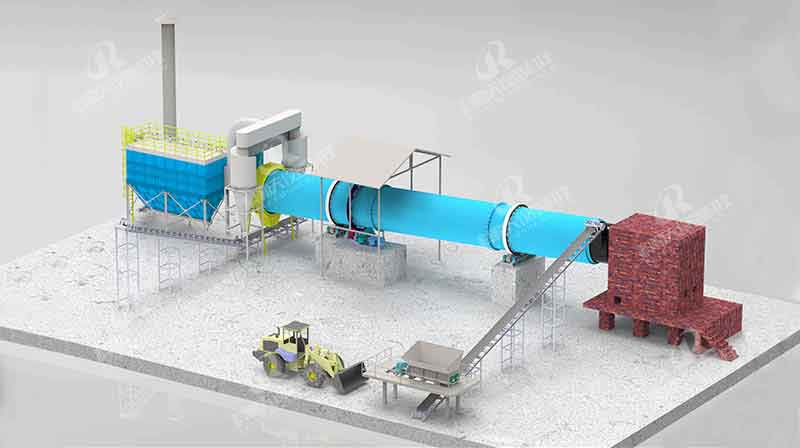

Considering the adverse drying conditions of coal slime, such as high moisture, high viscosity, high water holding capacity and low caloric value, etc. Henan Kolev equipment produces new generation coal slime drying complete system, using a new feeding, discharging device, to avoid the dryer feeding clogging, discontinuous, uneven and material return phenomenon, and reduce the dust removal system load.

Greatly reduce wear and power loss.

No plugging material, feeding and discharging more smooth, strengthen the dust removal effect.

The function of pre-crushing and cleaning is strengthened and heat conduction is improved.

The whole period of material falls, the heat exchange more sufficient, can easily reach the final moisture index.

|