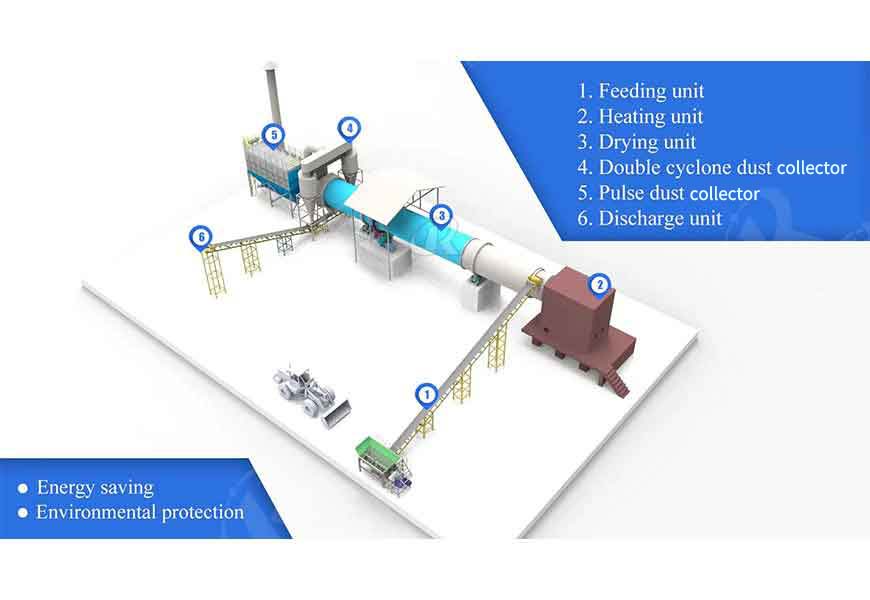

In view of the coal slime with high moisture, high viscosity, high water holding capacity and low calorific value and many other adverse drying conditions, Henan Kolev Machinery new generation Coal Slime Dryer using new feeding, discharging device, put an end to the roller dryer feeding clogging, discontinuous, uneven and material return phenomenon, reduce the dust removal system load.

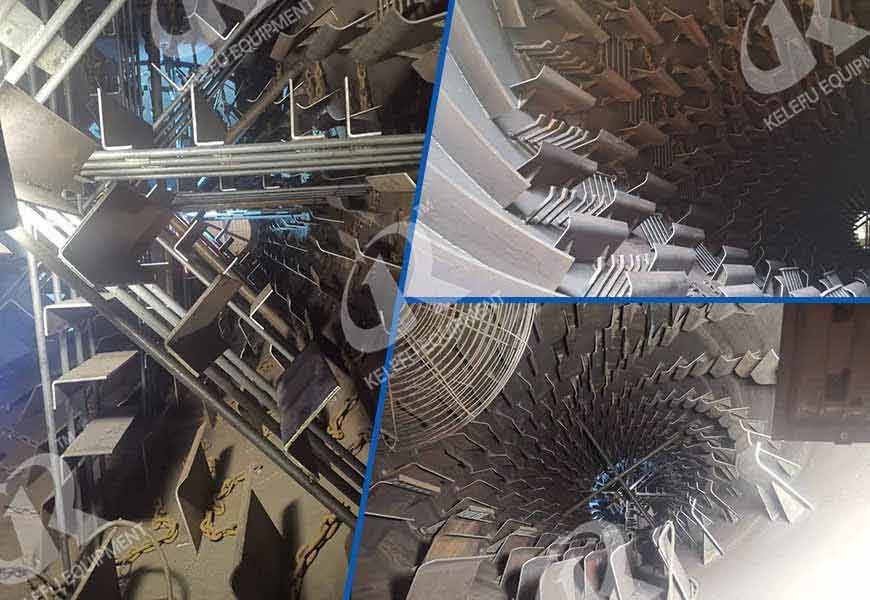

The industrialization, continuity and automation of coal slime drying have been realized by using a new type of non-power crushing device.

The use of downflow mode, unique inlet and outlet device, new internal structure, can change the operation parameters according to different material properties and finished product requirements, its strong load resistance, large handling capacity, less fuel consumption, low drying cost.

Enhanced dust removal device, a variety of heat sources to meet the environmental requirements of different areas.

Aligning tugboat design, achieve

| product standard(m) | Capacity(t/h) | Feed moisture(%) | Final Moisture(%) | Reducer number | Mounting inclination(°) | Power(KW) |

|---|---|---|---|---|---|---|

| 0.8*8 | 0.5-3 | 30% | 15%-1% | ZQ250 | 1.5-3 | 3kw |

| 1*10 | 1—5 | 30% | 15%-1% | ZQ250 | 1.5-3 | 5.5KW |

| 1.2*12 | 2_8 | 30% | 15%-1% | ZQ350 | 1.5-3 | 11KW |

| 1.6*16 | 6_10 | 30% | 15%-1% | ZQ400 | 1.5-3 | 15KW |

| 1.8*16 | 8—15 | 30% | 15%-1% | ZQ400 | 1.5-3 | 18.5kw |

| 2*18 | 10—20 | 30% | 15%-1% | ZQ500 | 1.5-3 | 22kw |

| 2.2*18 | 12—25 | 30% | 15%-1% | ZQ650 | 1.5-3 | 30kw |

| 2.4*22 | 15—30 | 30% | 15%-1% | ZQ650 | 1.5-3 | 45kw |

| 2.6*24 | 18—35 | 30% | 15%-1% | ZQ850 | 1.5-3 | 55kw |

| 2.8*26 | 20—40 | 30% | 15%-1% | ZQ850 | 1.5-3 | 75kw |

| 3*28 | 25—50 | 30% | 15%-1% | ZQ850 | 1.5-3 | 90kw |

| 3.2*28 | 30-60 | 30% | 15%-1% | ZSY315 | 1.5-3 | 110kw |

| 3.4*30 | 35-70 | 30% | 15%-1% | ZSY355 | 1.5-3 | 132kw |

| 3.6*32 | 40-80 | 30% | 15%-1% | ZSY400 | 1.5-3 | 160kw |

| 3.8*32 | 50-100 | 30% | 15%-1% | ZSY450 | 1.5-3 | 185kw |

.jpg)