The company is an enterprise mainly engaged in sand and stone processing and sales. Due to the development of production, they need to purchase a high-quality mechanism sand production line. After many understanding and field investigation, they were attracted by Kolev's professional technology and fine process, and specially introduced our advanced equipment technology and purchased a full set of granite sand making production line.

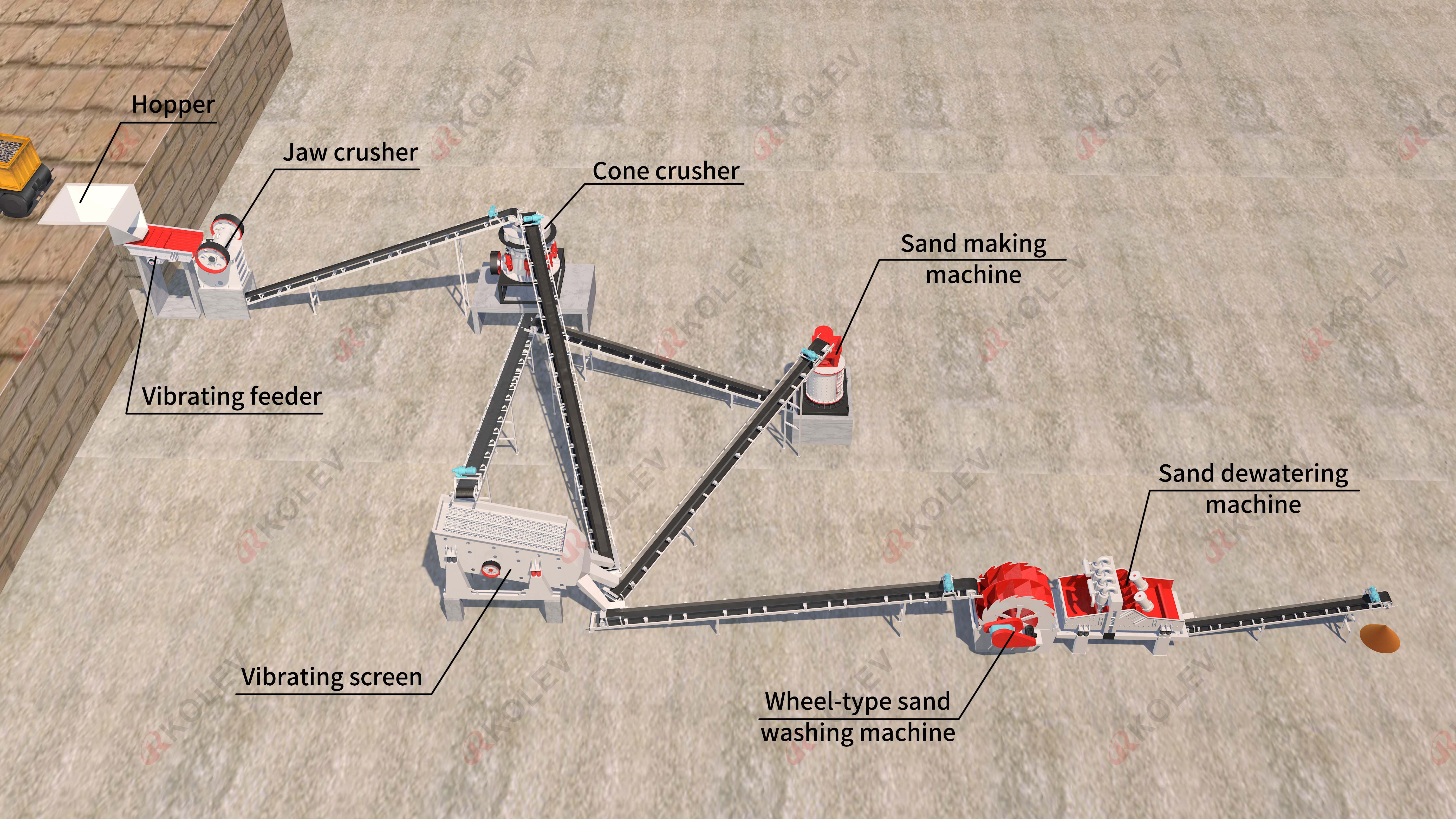

1. Granite is continuously fed into the jaw crusher by a vibrating feeder for primary crushing.

2. The coarsely crushed material is conveyed to the cone crusher by a belt for secondary crushing.

3. The crushed granite is screened and returned through a vibrating screen to ensure that the particle size entering the sand making machine is 30-40mm.

4. The screened granite is conveyed to the Vertical Hammer Sand Maker for crushing and shaping, and the finished product particle size is 0-5mm.

5. The mixed material from the sand making machine is separated according to different particle sizes. Separate qualified finished sand and returned sand (return to the sand making machine).

|

Specification model |

Simplified diameter | Capacity(t/h) | Feeding size(mm) |

Discharge size(mm) |

Yield | Motor power(kw) | Frequency conversion control cabinet (kw) |

| HYZS-29 | 29 | 10-20 | <50 | ≤3mm is adjustable |

60-95% | 37-45 | 50 |

| HYZS-39 | 39 | 20-40 | <65 | 55-75 | 90 | ||

| HYZS-49 | 49 | 30-60 | <70 | 90-110 | 160 | ||

| HYZS-59 | 59 | 50-100 | <85 | 132-160 | 200 | ||

| HYZS-69 | 69 | 80-160 | <100 | 220-250 | 210 | ||

| HYZS-79 | 79 | 120-240 | <120 | 132*2 | 280 |

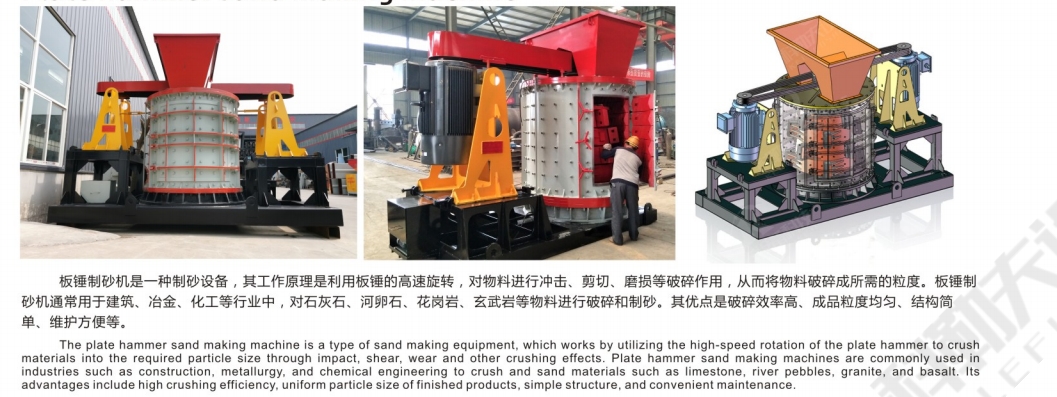

1. The material first falls vertically from the upper part of the machine into the high-speed rotating impeller.

2. Under the action of high-speed centrifugal force, it collides with another part of the material that is diverted around the impeller in an umbrella-shaped form, and then collides, rubs and crushes each other again or multiple times in the strong vortex formed between the impeller and the casing.

3. Finally, it is discharged from the discharge port at the bottom of the granite sand making machine, and then controlled by the screening equipment to reach the required finished product particle size.

1: The structure is simple and reasonable, and the production cost can be reduced by the improvement of the hammer head.

2:High crushing efficiency, excellent and fine granularity of the discharge material.

3: The finished product is a cube with high packing density and low noise of equipment operation.

4: With a variety of models,which can be used for various types of sand production lines, and also can be customized according to customer needs.