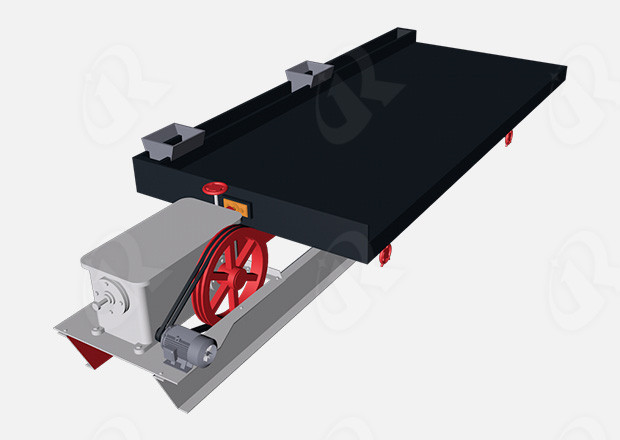

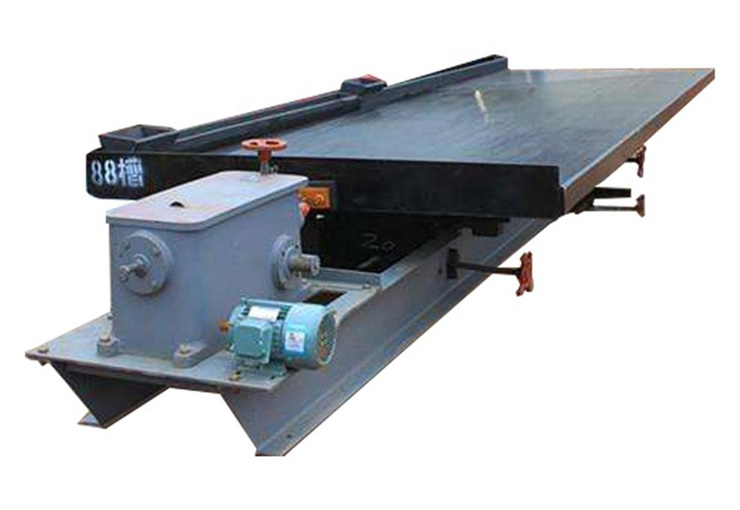

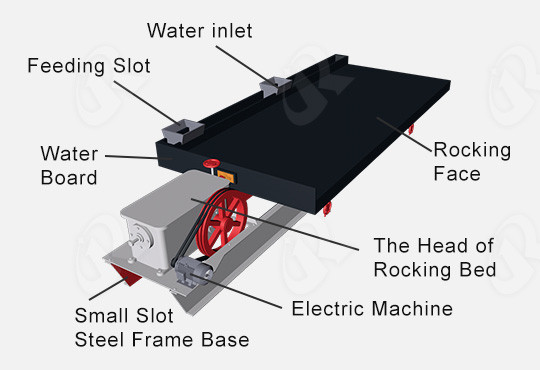

Shaking Table

Shaking Table is the main equipment of gravity beneficiation. It is easy to operate and can produce high-grade concentrate, sub-concentrate, medium ore and tailings at one time. It is an important ore separation equipment. Widely used for sorting tungsten, tin, niobium and other rare and precious metals. It can also be used to select iron-manganese ore and coal.

-

Capacity10-60t/d

-

Feed size0.15-2mm

Shaking Table is one of the gravity ore dressing main equipment.It is easy to operate as it can produce high level concentrate,second concentrate,and middling products and tailings at one time,it is the important ore dressing equipment.It is widely used to separate wolfram,tin,niobium,other rare metal and precious metal ore and also used to separate iron,manganese and coal,etc.

Shaking table at the gravity separating process has advantages of high enrichment ore rate efficiency,easy to operate and adjust,can achieve final fine ore and final tailing once,etc.

Widely used in the separation of tin, tungsten, gold and silver, lead, zinc, tantalum, niobium, iron, manganese, ferro-titanium and coal, etc.

Shaking table beneficiation is a process in which mineral particles are loosely layered and separated on the bed surface by means of the combined action of mechanical slab symmetric reciprocating motion and thin-layer inclined water flow on the inclined bed surface, so that the minerals are sorted according to different densities.

Name | Coarse sand table | Fine sand table | Slime table | |

Table Dimension | Length(mm) | 4450 | 4450 | 4450 |

Gearing side wide(mm) | 1855 | 1855 | 1855 | |

Concentrate side wide(mm) | 1546 | 1546 | 1546 | |

Max feed-in material size(mm) | 2 | 0.5 | 0.15 | |

Feed-in material capacity(t/d) | 30-60 | 10-20 | 15-25 | |

Feed-in material concentration(%) | 25-30 | 20-25 | 15-25 | |

Travel length(mm) | 16-22 | 11-16 | 8-16 | |

Frequency(f) | 15-48 | 48-53 | 50-57 | |

Water for cleaning table(t/d) | 80-150 | 30-60 | 10-17 | |

Transverse gradient | 2.5-4.5 | 1.5-3.5 | 1-2 | |

Longitudinal gradient(%) | 1.4 | 0.92 | -- | |

Table final angle | 32-42 | 40 | 42 | |

Dressing area | 7.6 | 7.6 | 7.6 | |

Table length ratio | 2.6 | 2.6 | 2.6 | |

Power(kw) | 1.1 | 1.1 | 1.1 | |

+86 166-3801-7614

+86 166-3801-7614