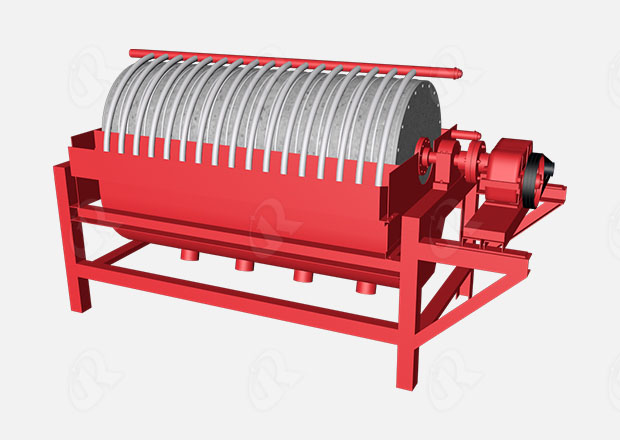

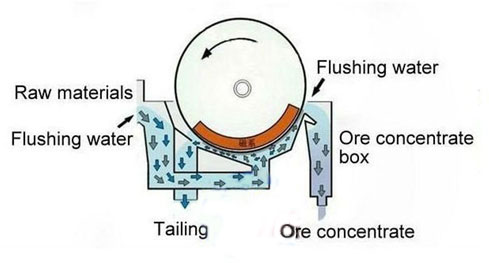

Wet magnetic separator is widely used in beneficiation plant, coal washing and chemical departments for wet sorting particle size 6-0 mm strong magnetic minerals, and the mineral is divided into two products of the magnetic material and non-magnetic material. Strong magnetic minerals selected by it magnetic susceptibility should not be less than 3000 * 106 cm3 / g, belonging to such minerals are magnetite, pyrrhotite,etc. Hematite, limonite, Ling iron, should be selected for magnetization roasting in order to carry out the sorting.Same cylinder can be equipped with three tanks, that is half-countercurrent tank, countercurrent tank, downstream groove to adapt different sorting process.

The magnetic system all adopts NdFeB magnets with high magnetic energy product and high coercive force, with high magnetic field strength and large action depth

Drum diameter(mm) | Barrel length (mm) | Barrel table field(kA/m) | Throughput(t/h) | Feeding size (mm) | Power(KW) | Weight(t) | |

KL406 | 400 | 600 | 80~450 | 2~4 | 2~0 | 0.55 | 0.4 |

KL603 | 600 | 300 | 80~400 | 2~4 | 2~0 | 0.55 | 0.4 |

KL606 | 600 | 600 | 80~400 | 5~10 | 2~0 | 1.1 | 0.95 |

KL609 | 600 | 900 | 80~400 | 8~15 | 2~0 | 1.5 | 1.3 |

KL612 | 600 | 1200 | 80~400 | 10~20 | 2~0 | 1.5 | 1.5 |

KL618 | 600 | 1800 | 80~400 | 15~30 | 2~0 | 1.5 | 1.8 |

KL712 | 750 | 1200 | 120~400 | 12~25 | 2~0 | 1.5 | 2.0 |

KL718 | 750 | 1800 | 120~400 | 30~45 | 2~0 | 3.0 | 2.2 |

KL724 | 750 | 2400 | 120~400 | 30~65 | 2~0 | 3.0 | 2.5 |

KL918 | 900 | 1800 | 130~400 | 35~60 | 3~0 | 4.0 | 2.8 |

KL924 | 900 | 2400 | 130~400 | 70-110 | 3~0 | 4.0 | 3.5 |

KL1018 | 1050 | 1800 | 130~400 | 40-75 | 3~0 | 4.5 | 3.5 |

KL1021 | 1050 | 2100 | 130~400 | 50-80 | 3~0 | 5.5 | 3.5 |