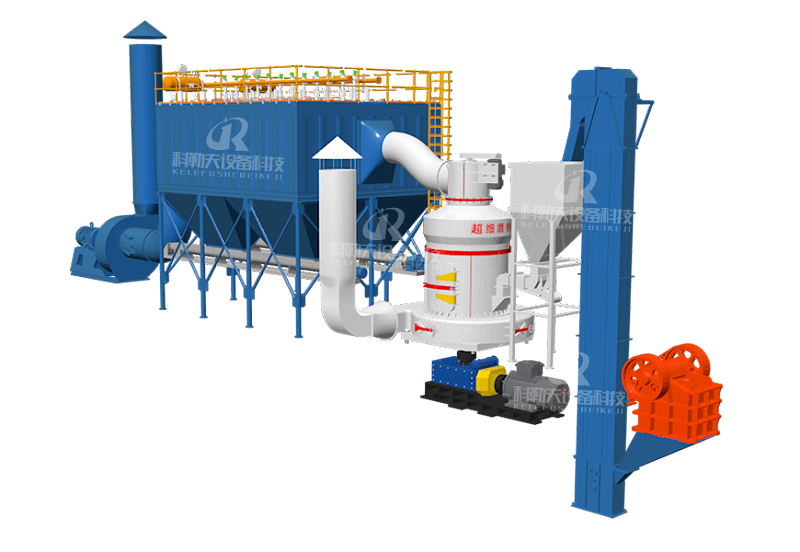

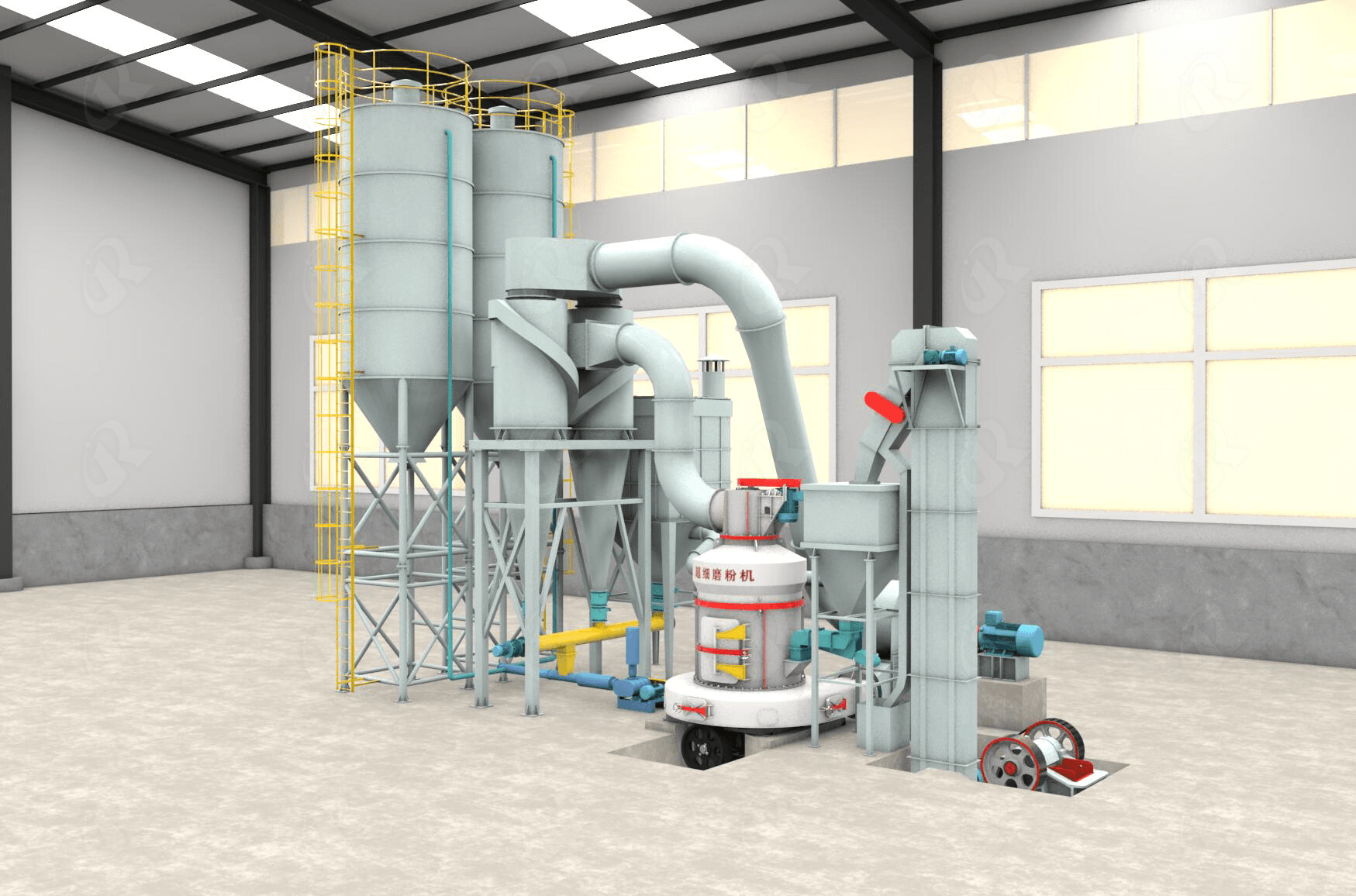

The whole set of Ultrafine grinding mill is composed of crusher, bucket elevator, hopper, screw feed scale, superfine mill host, separator, pulse dust collector, fan and electric control system, etc.

It is capable of continuous production, large production capacity, high grinding efficiency, multiple sorting heads, uniform fineness of finished products, easy to adjust fineness, and small energy loss.

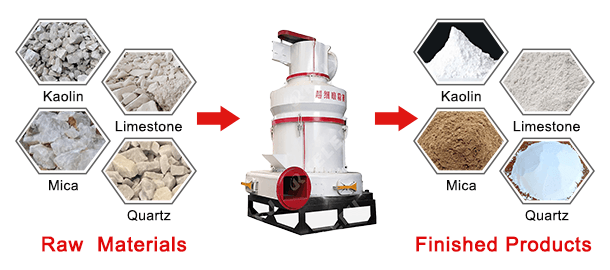

Strong adaptability to materials, it can grind a variety of hardness of non-metallic ores.

The analyzers of the mill are used with multiple heads, and the fineness of the separating materials is uniform and controllable. The classifier can produce two kinds of fine powder with more than 800 mesh at the back end.

The equipment has compact structure, less transmission parts, low maintenance cost, stable operation and easy installation.

| Model | KL1100 | KL1450 | KL1760 | KL1950 | KL2100 |

| Handling ability (t/h) | 2-6 | 6-10 | 8-20 | 15-30 | 20-40 |

| Main motor power(kw) | 45 | 90 | 132 | 185 | 220 |

| Fan power(kw) | 45 | 100 | 160 | 185 | 220 |

| Analyst power(kw) | 15 | 18.5 | 22 | 37 | 45 |

| Rotate speed(r/m) | 120 | 90 | 90 | 90 | 90 |

| Diameter of grinding ring(mm) | 1100 | 1450 | 1760 | 1950 | 2100 |

| Diameter of grinding roll(mm) | 320 | 420 | 450 | 570 | 630 |

| Maximum feed(mm) | 25 | 30 | 30 | 40 | 40 |

| Finished particle size(mm) | 1.6 ------ 0.013 | ||||

| Weight(t) | 16 | 28 | 55 | 68 | 95 |