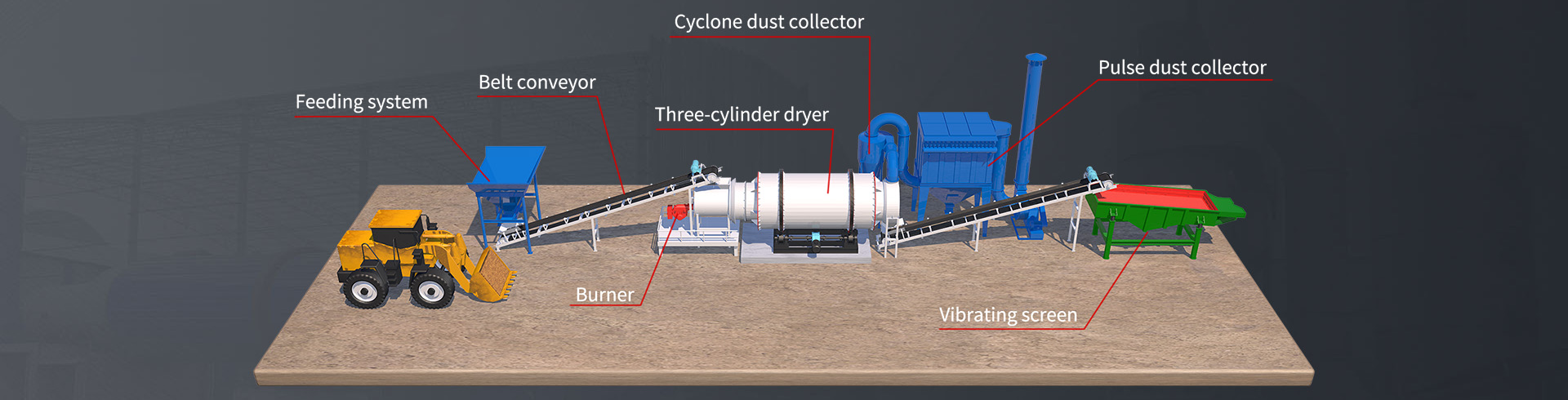

Sand dryer is also known as the three layers of drum dryer, three return cylinder dryer, on the basis of the single-cylinder dryer, developed and manufactured, which is an industrial dryer on Granular material. with mature technology, through the drying of the sand, fly ash, coal, mineral materials, slag, and other material, the effect is very good.

It is made of wear-resistant manganese plate, and the new alloy lifting plate device is used inside, which is wear-resistant and durable and has a long service life.

The angle of the new lifting plate device is seriously designed according to the characteristics of the material, which can increase the heating area of the material, sand drying plant thermal efficiency is as high as 80%, at the same time, the total power is low, 40% energy saving..

Three tube overlapping, small area, reduce investment in civil construction.The sand dryer covers an area of about 40% lower than single drum dryer and civil investment reduced by about 50%.

Adopt new transmission system, upgrade version reducer, strong power, more stable operation.

| Specifications and Models | Handling Capacity Drying Sand(t/h) | Finished Product Moisture(%) | Power(KW) |

| KLF-TH1216 | 1-3 | <2±1 | 4 |

| KLF-TH1630 | 3-5 | <2±1 | 4 |

| KLF-TH2240 | 8-10 | <2±1 | 4 |

| KLF-TH2460 | 10-15 | <2±1 | 7.5 |

| KLF-TH2660 | 15-20 | <2±1 | 15 |

| KLF-TH2870 | 25-30 | <2±1 | 18.5 |

| KLF-TH3080 | 30-40 | <2±1 | 22 |

| KLF-TH3290 | 40-50 | <2±1 | 45 |

| KLF-TH3390 | 50-60 | <2±1 | 55 |

| KLF-TH3610 | 70-80 | <2±1 | 75 |

| The above parameters are for reference only. For more details, please contact customer service | |||