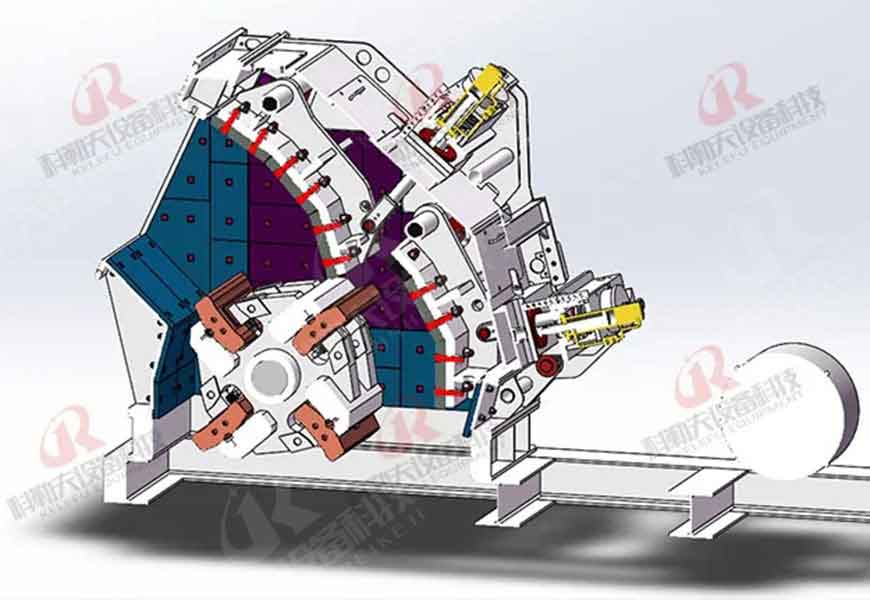

Large Mouth Impact Crusher is a new generation of impact crusher developed by our company on the basis of traditional impact crusher combined with the specific mining conditions of sand and gravel industry. Compared with traditional impact crusher, it can not only ensure the advantages of impact crushing particle type, but also greatly improve the crushing ratio and output. It is mainly used in hydropower, highway, waste disposal of building materials and artificial construction aggregate processing.

Hydraulic automatic adjustment of the counter frame and the gap between the plate hammer, convenient, fast.

Using the special heavy rotor design principle, has greater rotation inertia, improve the crushing efficiency, and has the effect of energy saving.

Using hydraulic lifting and maintenance lifting device, can quickly complete the plate hammer and other wearing parts replacement, reduce downtime and equipment maintenance time, reduce maintenance costs.

Bearing seat adopts the principle of integrated design, the interior adopts multi-stage sealing, dustproof and waterproof effect is good; The interior lining board adopts modular design, which makes the wearing parts play a large use efficiency.

| Specification | Rotor size(mm) | Max feed size (mm) | Discharge size(mm) | Capacity(m3/h) | Power(kw) | |

| 150Mpa | 250Mpa | |||||

| PFQ0808 | ф850×750 | 200 | 150 | 25(80-90%) | 40 | 55 |

| PFQ1108 | ф1040×750 | 300 | 180 | 30(80-90%) | 95 | 90 |

| PFQ1110 | ф1040×1000 | 400 | 200 | 35(80-90%) | 110 | 110 |

| PFQ1310 | ф1280×1000 | 500 | 250 | 40(80-90%) | 175 | 160 |

| PFQ1313 | ф1280×1250 | 600 | 250 | 40(80-90%) | 220 | 220 |

| PFQ1315 | ф1280×1500 | 700 | 300 | 50(80-90%) | 285 | 300 |

| PFQ1515 | ф1450×1500 | 1000 | 350 | 50(80-90%) | 400 | 400 |

| PFQ1520 | ф1450×2000 | 1000 | 400 | 50(80-90%) | 540 | 550 |