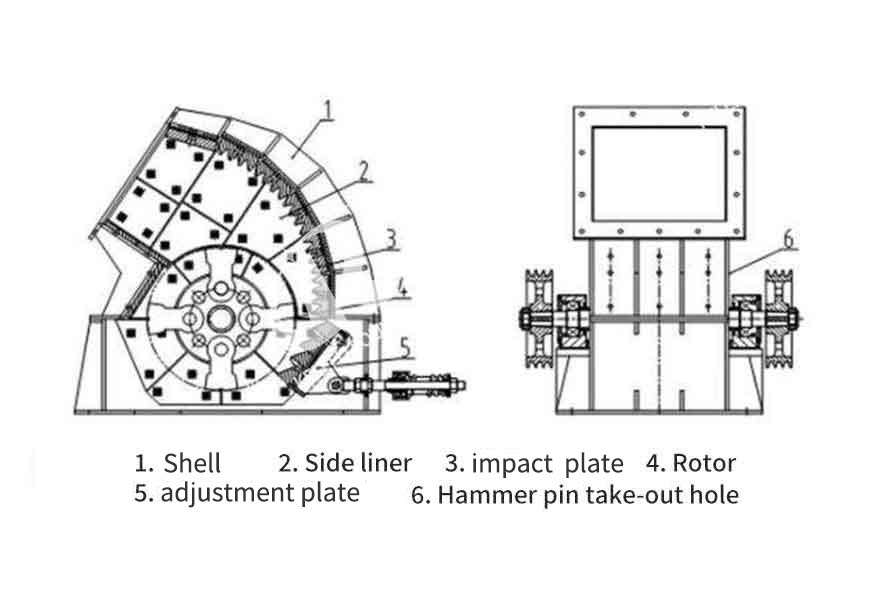

The heavy hammer crusher uses a high-speed rotating hammer head to impact the ore, causing the ore to rupture along its natural fractures, layers and joint surfaces. Generally, the hammer crusher with heavy hammer head, small number of hammer, slow speed, with upper grate and hammer disk structure can enter large particle size materials, and should be used as medium crushing or a certain range of coarse crushing.

The crushing equipment has a high degree of automation, and the crushing ratio is large. After crushing, the products are cube shaped, with low content of needles and sheets, no internal cracks, high compressive strength, good particle shape and high yield of finished products.

Low investment is high yield. The wearing parts of the equipment are made of domestic raw materials with strong compressive resistance and wear-resistant, with small loss and long service life, which can reduce the input cost and bring considerable economic benefits to customers.

After several improvements and optimization of the equipment, the structure design is more reasonable, the operation is more convenient, the use cycle of parts is long, the user in the equipment maintenance and parts replacement of the total cost is lower.

The finished material can be adjusted according to the demand. The coarse, medium and fine specifications are complete. The broken product has no sheet, no smooth body, and the multi-angle and multi-edge guarantee the compressive strength.

| Model | Feed port size (mm) | Feed size (mm) | Capacity(t/h) | Power (kw) |

| PCZ1308 | 850×800 | ≤600 | 100-160 | 132 |

| PCZ1510 | 1000×900 | ≤700 | 160-210 | 132×2 |

| PCZ1512 | 1200×900 | ≤750 | 250-320 | 160×2 |

| PCZ1615 | 1500×1200 | ≤1000 | 420-500 | 200×2 |

| PCZ1620 | 2000×1200 | ≤1200 | 800-1000 | 400×2 |

| PCZ1820 | 2000×1200 | ≤1200 | 1000-1200 | 450×2 |

| PC0706 | 618×510 | ≤400 | 50-70 | 75 |

| PC0808 | 780×610 | ≤500 | 80-100 | 132 |

| PC0910 | 1070×750 | ≤600 | 150-200 | 110×2 |

| PC1012 | 1255×810 | ≤650 | 250-300 | 132×2 |

| PC1213 | 1350×920 | ≤750 | 300-350 | 160×2 |

| PC1216 | 1530×920 | ≤750 | 400-500 | 200×2 |

| PC1220 | 2000×920 | ≤750 | 500-600 | 220×2 |