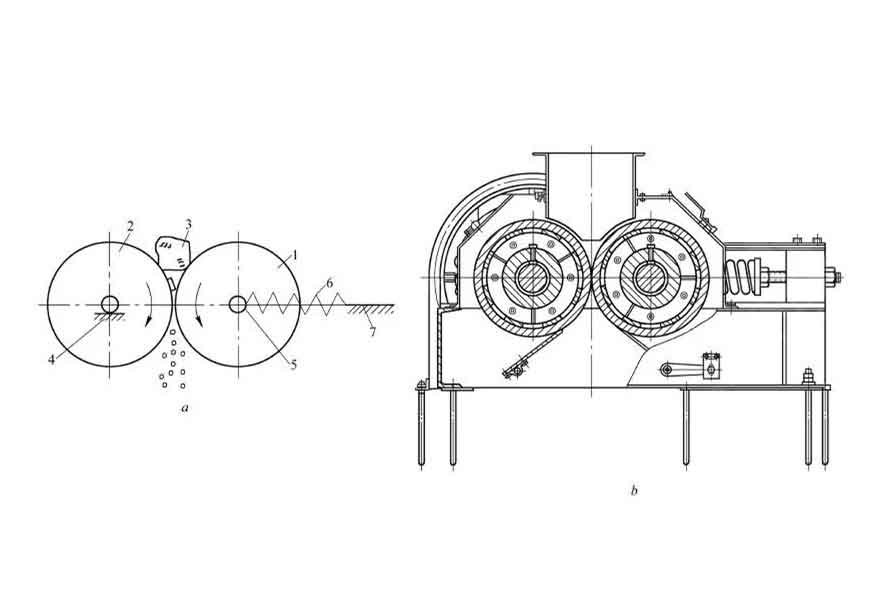

The main structure includes motor wheel, motor, belt, flywheel, bearing seat, rotor, buffer spring, frame, shell, roller body, horizontal support, etc., occupying a smaller area, lighter weight, more conducive to the operation and maintenance of operators.

The roller sand machine has the characteristics of large crushing capacity and high crushing efficiency.

Using the selective crushing method, the probability of the particle is higher in the shape of cube, uniform forming, basically do not need to go through the secondary processing, save the working time, improve the working efficiency.

The abrasive lining board is equipped with replaceable wear-resistant lining board. The wear-resistant lining board is made of domestic advanced wear-resistant material, which has the advantages of long service life, not easy to damage and convenient maintenance.

The over-crushing phenomenon of the roller sand machine is less, the shape, size and arrangement of the teeth on the roller surface can be changed with the properties of the material, and the medium and fine crushing of medium hard and soft ore can be carried out.

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roll diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roll width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Feed size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharge size(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Power model | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |